PM TECHNOLOGY PRODUCTS

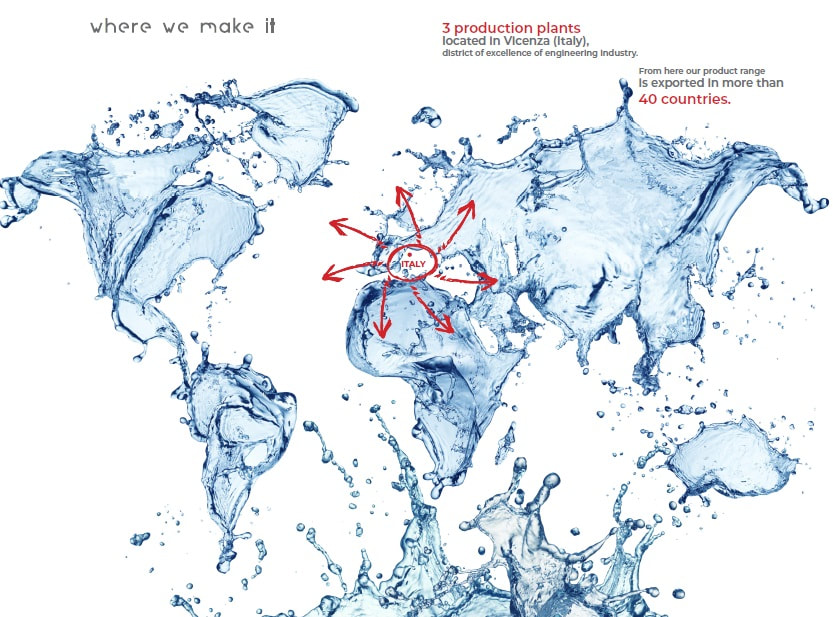

PM S.r.l. - PM Technology was established in Italy in 2008 to become one of the leading Italian companies producing submersible pump drive motors and electronic pump control products. Focussing on OEM, European and International markets.

PM S.r.l. claims "Our strengths are based on over 30 years of experience of the founding partner applied to the most modern manufacturing and product technologies coupled with in-depth knowledge of international markets."

"As a result PM Technology has managed to establish itself as a modern, dynamic company focusing on continuous improvement. Each PM product is the expression of careful and enthusiastic work based on research and design with exclusive attention to performance, quality of the materials used and highest competitiveness possible. The result is an extremely reliable and efficient product range in which every detail is carefully researched, all distinguishing features of Made in Italy excellence. These key elements which embody profound love for an art passed down from father to son currently guide PM S.r.l."

PM S.r.l. claims "Our strengths are based on over 30 years of experience of the founding partner applied to the most modern manufacturing and product technologies coupled with in-depth knowledge of international markets."

"As a result PM Technology has managed to establish itself as a modern, dynamic company focusing on continuous improvement. Each PM product is the expression of careful and enthusiastic work based on research and design with exclusive attention to performance, quality of the materials used and highest competitiveness possible. The result is an extremely reliable and efficient product range in which every detail is carefully researched, all distinguishing features of Made in Italy excellence. These key elements which embody profound love for an art passed down from father to son currently guide PM S.r.l."

Pm technology products in stock - Adelaide

4WPO SET

4” submersible pump set ready to use. No complicated electrical connection required, just lower the pump into the water bore, well or tank and plug in 230v power supply.

4WPO SET series consists of:

4OM MOTOR CONSTRUCTION FEATURES:

PARTS IN CONTACT WITH WATER in AISI 304 stainless steel.

EXTERNAL SLEEVE AND BOTTOM made in AISI 304L stainless steel.

UPPER BRACKET made in cast iron with cataphoresis treatment

and protected with an AISI 304 stainless steel cover.

MECHANICAL SEAL made in graphite/ceramic.

STATOR with 24 slots, specifically developed to achieve maximum electrical yield.

REMOVABLE POWER CABLE-CONNECTOR

SHAFT made in carbon-steel alloys in the rotor area, to foster electrical features. AISI 304 stainless steel projection.

SAND PROTECTION FILTER that stops any impurities that may get in contact with the external face of mechanical seal. This ensures a longer mechanical seal lifetime.

4WP PUMP CONSTRUCTION FEATURES

IMPELLERS floating type made with Noryl® for a superior sand handling.

STRAINER made in stamped 304 stainless steel.

DISCHARGE OUTLET AND NON-RETURN VALVE made in 304 stainless steel.

PUMP SHAFT made in AISI 304 stainless steel.

PUMP SLEEVE made in AISI 304 stainless steel.

C-BOX ELECTRIC PANEL CONSTRUCTION FEATURES

Box made of thermoplastic insulating material

On / Off switch

Externally resettable thermal protection

Output with cable glands

IP 54 protection class

OPERATING LIMITS:

DEGREE OF PROTECTION - IP 68

INSULATION CLASS - F

VOLTAGE TOLERANCE -10% / +10%

PUMPED LIQUID TEMPERATURE - 0°C – 35°C

MIN. COOLING FLOW - 0,1 m/s

MAX. STARTS / HOUR - 30

MAX. AMOUNT OF SAND TOLERATED IN WATER - 150 g/m3

MOUNTING - Vertical and/or horizontal

MAX. IMMERSION DEPTH 200 m

4” submersible pump set ready to use. No complicated electrical connection required, just lower the pump into the water bore, well or tank and plug in 230v power supply.

4WPO SET series consists of:

- 4” rewindable oil filled submersible motor 4OM;

- 4” submersible pump 4WP;

- safety rope made in Nylon;

- Submersible pump power cable connected to the pump.

- C-BOX electrical Starter Box including 3-pin 230v plug connector.

4OM MOTOR CONSTRUCTION FEATURES:

PARTS IN CONTACT WITH WATER in AISI 304 stainless steel.

EXTERNAL SLEEVE AND BOTTOM made in AISI 304L stainless steel.

UPPER BRACKET made in cast iron with cataphoresis treatment

and protected with an AISI 304 stainless steel cover.

MECHANICAL SEAL made in graphite/ceramic.

STATOR with 24 slots, specifically developed to achieve maximum electrical yield.

REMOVABLE POWER CABLE-CONNECTOR

SHAFT made in carbon-steel alloys in the rotor area, to foster electrical features. AISI 304 stainless steel projection.

SAND PROTECTION FILTER that stops any impurities that may get in contact with the external face of mechanical seal. This ensures a longer mechanical seal lifetime.

4WP PUMP CONSTRUCTION FEATURES

IMPELLERS floating type made with Noryl® for a superior sand handling.

STRAINER made in stamped 304 stainless steel.

DISCHARGE OUTLET AND NON-RETURN VALVE made in 304 stainless steel.

PUMP SHAFT made in AISI 304 stainless steel.

PUMP SLEEVE made in AISI 304 stainless steel.

C-BOX ELECTRIC PANEL CONSTRUCTION FEATURES

Box made of thermoplastic insulating material

On / Off switch

Externally resettable thermal protection

Output with cable glands

IP 54 protection class

OPERATING LIMITS:

DEGREE OF PROTECTION - IP 68

INSULATION CLASS - F

VOLTAGE TOLERANCE -10% / +10%

PUMPED LIQUID TEMPERATURE - 0°C – 35°C

MIN. COOLING FLOW - 0,1 m/s

MAX. STARTS / HOUR - 30

MAX. AMOUNT OF SAND TOLERATED IN WATER - 150 g/m3

MOUNTING - Vertical and/or horizontal

MAX. IMMERSION DEPTH 200 m

For the latest pricing and availability contact us on -