Quality Italian submersible bore pumps

Exa Pumps srl is a family company, specialized in the design and manufacture of submersible pumps.

It was founded in the 1990’s, as Felsom srl, taking the know-how of the company that was part of the Aturia Group. Nowadays the company is managed by the third generation and exports its products all over the world, both with the EXA brand and with the F.EL.SOM brand.

The company’s priority is the continued commitment to the study and development of innovative products that can continue to compete on the global market.

At Waterborepump Warehouse we are very pleased to be bringing this product into the Australian market.

It was founded in the 1990’s, as Felsom srl, taking the know-how of the company that was part of the Aturia Group. Nowadays the company is managed by the third generation and exports its products all over the world, both with the EXA brand and with the F.EL.SOM brand.

The company’s priority is the continued commitment to the study and development of innovative products that can continue to compete on the global market.

At Waterborepump Warehouse we are very pleased to be bringing this product into the Australian market.

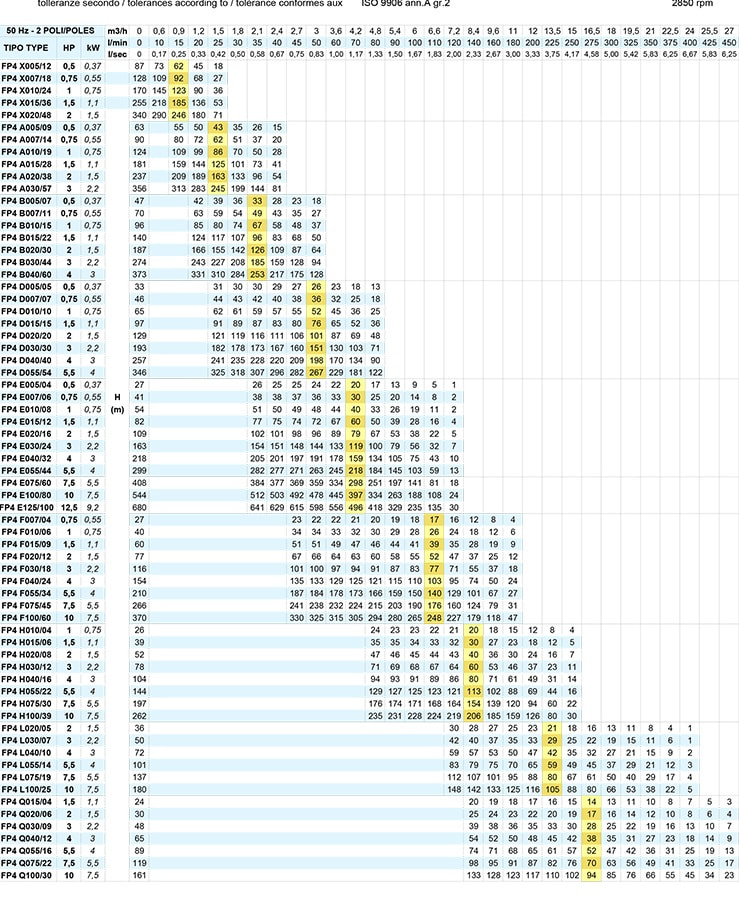

The EXA Pumps 4” Submersible pumps of the FP4 series are of a new design, very solid and compact and almost maintenance fee. The end housings are stainless steel AISI 304, manufactured with wax casting process, ensuring great robustness and reliability of the pump. The new patented design of independent floating impeller guarantees a low axial load on the motor and sand handling capacity of up to 250g/m3.

The new materials used in the construction, certified for use in drinking water, allow the pump to run even dry without damage—for short periods of time. To guarantee the reliable operation though, the water level should be at least one meter above the pump suction.

The new materials used in the construction, certified for use in drinking water, allow the pump to run even dry without damage—for short periods of time. To guarantee the reliable operation though, the water level should be at least one meter above the pump suction.

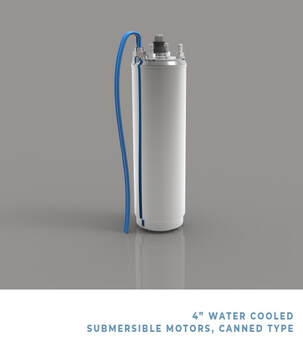

To match the high quality EXA FP4 pump wet end we are packaging our Waterborepump Warehouse Italian pump sets with the PM Technology 4WM 4” submersible 230v 3-wire motor, water cooled, resin encapsulated design. Motors designed to work in 4” or wider wells.

The use of very high quality Made in Italy materials and strict tests together with consolidated know how ensure high mechanical resistance and high performing electrical features. All parts in contact with water are in AISI 304 stainless steel which ensures resistance to corrosion even in the most extreme conditions of use. The STATOR with 24 slots, specifically developed to achieve maximum electrical performance. Airtight sealed and resin encapsulated. A solution which ensures excellent heat exchange and extremely high mechanical resistance with high pressure, something typical of very deep immersions. The Kingsbury-type THRUST BEARING SYSTEM with stainless steel thrust bearing runners oscillating on a self-aligning system. 100% TESTED: all motors are tested at the end of the line.

The use of very high quality Made in Italy materials and strict tests together with consolidated know how ensure high mechanical resistance and high performing electrical features. All parts in contact with water are in AISI 304 stainless steel which ensures resistance to corrosion even in the most extreme conditions of use. The STATOR with 24 slots, specifically developed to achieve maximum electrical performance. Airtight sealed and resin encapsulated. A solution which ensures excellent heat exchange and extremely high mechanical resistance with high pressure, something typical of very deep immersions. The Kingsbury-type THRUST BEARING SYSTEM with stainless steel thrust bearing runners oscillating on a self-aligning system. 100% TESTED: all motors are tested at the end of the line.

| |||||||